ACTIVITY

For consultation and inquiry, please fill out the inquiry form to the Center for Nano-satellite Testing

Check here before requesting the test.

- Test request form (Word)

- Equipment use application form (Word)

- Testing fee

- Satellite Testing Tutorial

Satellite environmental test

Thermal environment testing

Every satellite undergoes extreme thermal cycles in the space environment routinely ranging ±100℃. Various types of thermal environment tests are necessary to confirm whether a satellite can function properly in orbit. At CENT, facilities for vacuum thermal shock, thermal vacuum and equilibrium, thermal cycle, and thermo-optical property measurement are available.

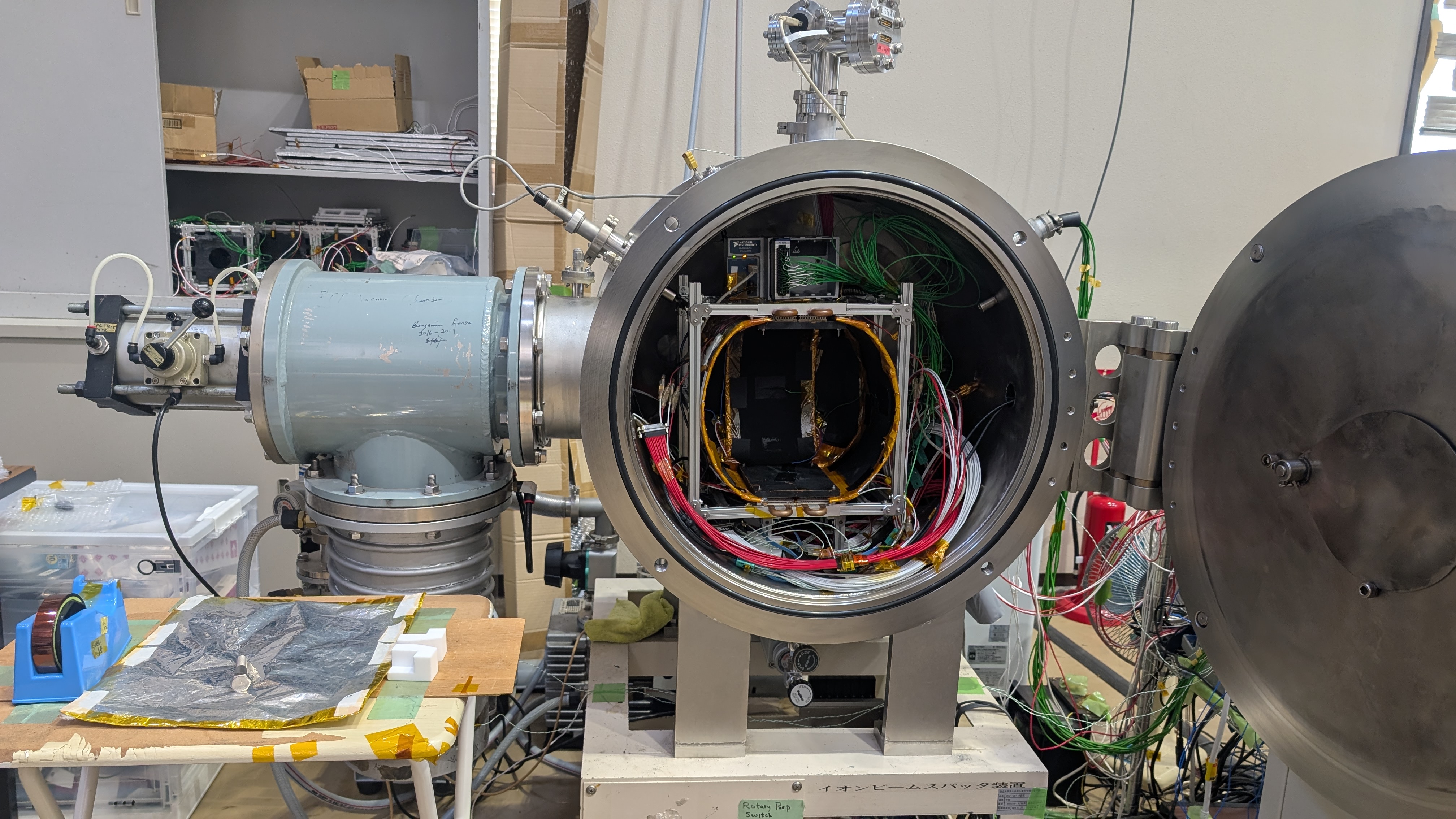

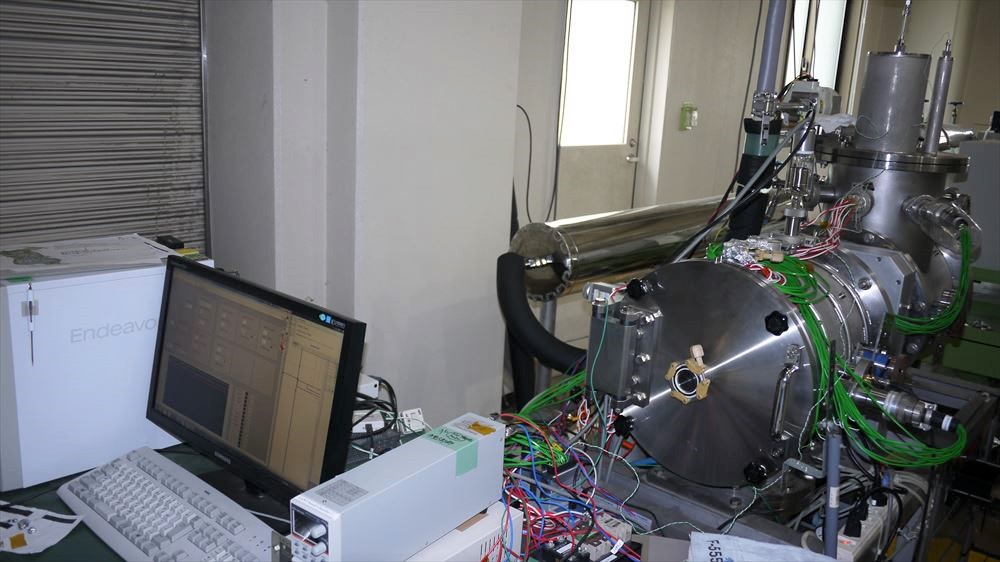

Thermal vacuum (small)

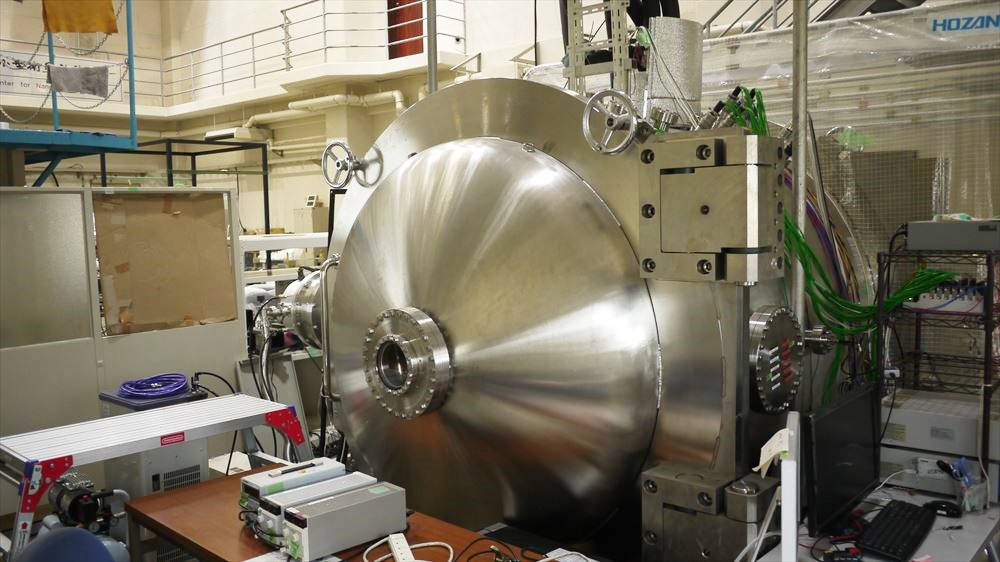

Thermal vacuum (large)

-150℃~+150℃ 1×10-5Torr or lower

Verifying operation in

vacuum at high temperature and low temperature

-60℃~+80℃ 1×10-5Torr or lower

Verifying operation in

vacuum at high temperature and low temperature

Thermal cycle

Thermo-optical measurement

-150℃~+150℃

Accelerated test on repetition of high and low

temperature Evaluation of characteristics of thermal control material

EMC testing

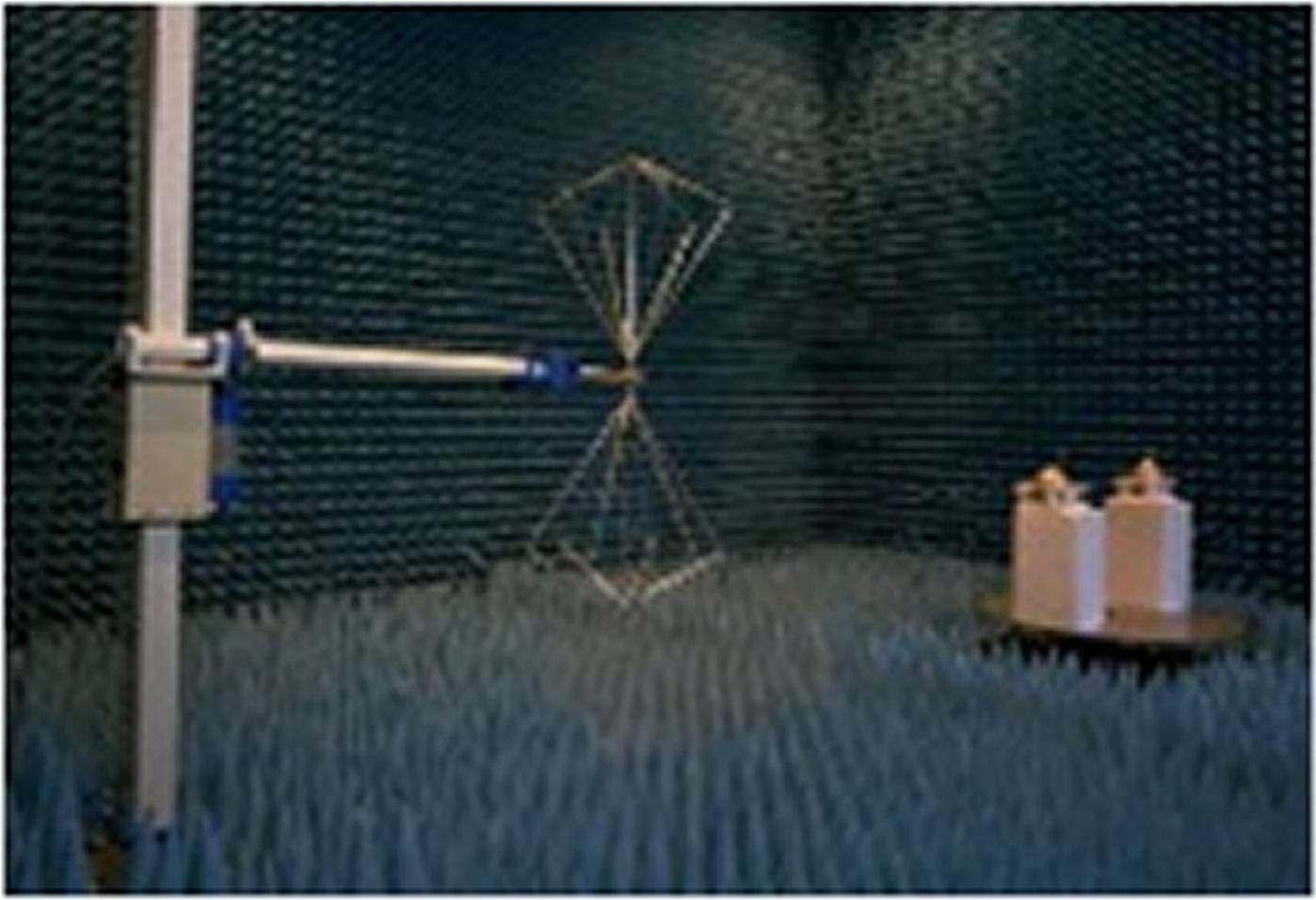

It is necessary to measure the radiation pattern from the onboard antenna to confirm that the satellite can communicate with the Earth ground station. It is also necessary to carry out electromagnetic compatibility (EMC) test to confirm that the satellite can withstand the electromagnetic environment produced by itself and others.

EMC testing

Antenna pattern measurement Electromagnetic Compatibility Testing

Vibration and shock testing

When a satellite is launched into space, it receives a great deal of shock and vibration during the blast-off. CeNT conducts the mechanical tests that verify that the satellite will survive this shock and vibration.

Vibration Test acquired ISO-17025 certification

Shock test

Max 2000G

Vibration test

50kg,Max 15G

Outgas measurement system

In orbit or during launch, outgassing may be harmful to onboard instruments or to other satellites sharing the launch. At CeNT the outgas property of material samples are tested to the ASTM E-595 standard.

Outgas measurement system

Clean room

Flight model should be assembled, integrated and tested in a clean environment. The center provides a clean room (80m2) of class 8 or better. Further cleanness can be achieved by using a clean booth additionally.

Clean room